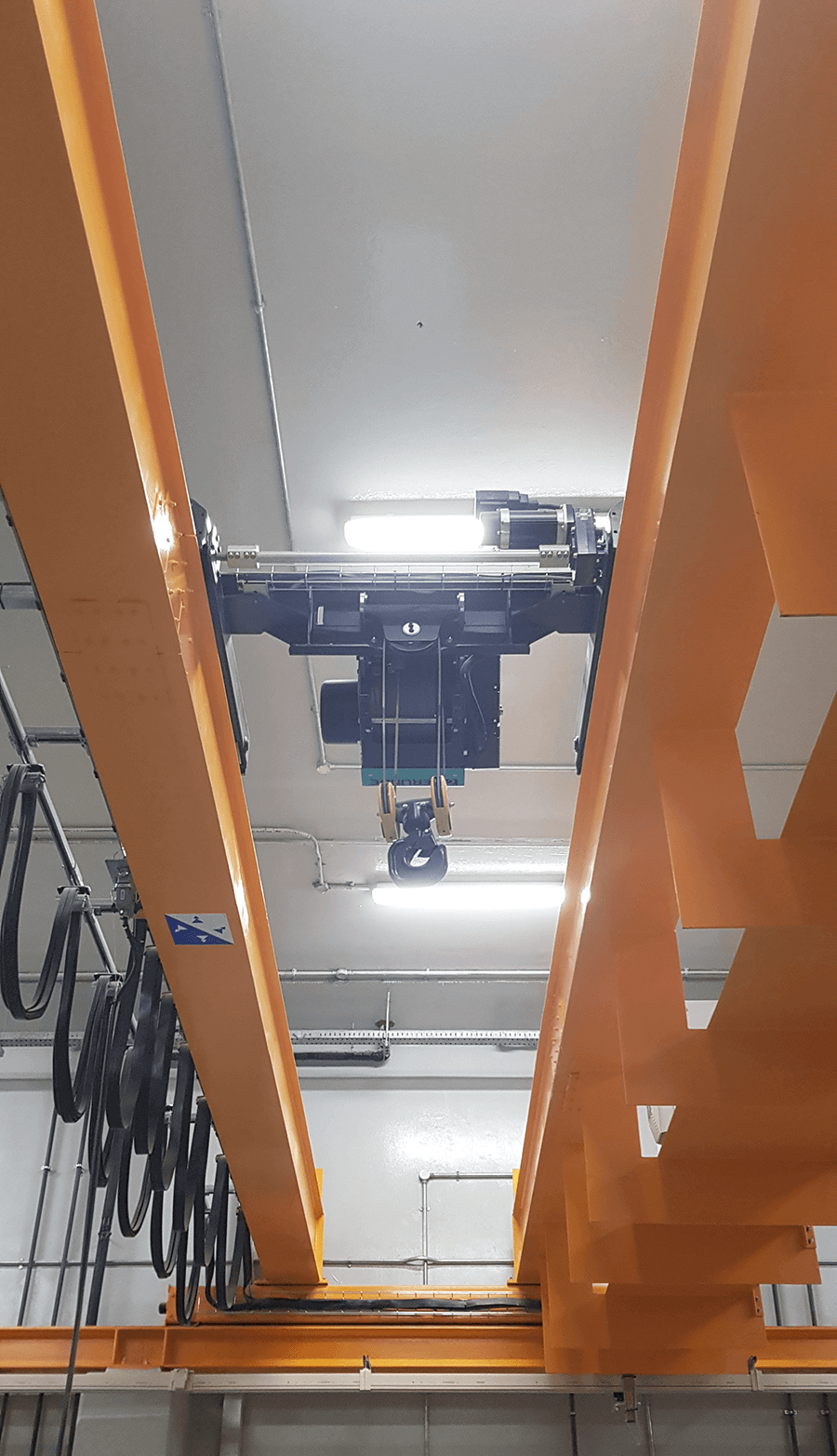

Double Girder EOT Cranes

DOUBLE GIRDER ELECTRIC OVERHEAD TRAVELLING (EOT) CRANES are critical in many industrial sectors due to their capacity for heavy lifting, larger span and Height of lift. Ranging from 1t to 250t Here are the primary uses and advantages of Double Girder EOT cranes:

- Material Handling – They are capable of lifting very heavy loads, making them ideal for industries like steel manufacturing, power plants, shipbuilding, and heavy engineering workshops Wide Span and maximum Height of Lift. Suitable for applications requiring wide spans and extensive coverage, such as large industrial buildings and warehouses.

- Precision Loading – Smooth Operation: These cranes allow for precise control over load movement due to its maximum stability as hoists will be running on top of Crane Girder, which is crucial in industries that require exact placement of heavy components, like automotive and aerospace manufacturing.

- Construction Industry – Double Girder Overhead Cranes are used to lift and place heavy construction materials, including steel beams and concrete panels, at precise locations on construction sites.

- Maintenance and Repair – Single girder EOT cranes are also used in maintenance and repair workshops for lifting and positioning heavy parts and machinery. This is crucial in industries like automotive, aerospace, and heavy machinery, where precise handling of components is required.

- Manufacturing – Assembly Lines: They assist in moving large components through various stages of production, enhancing efficiency and reducing manual labor in manufacturing plants.

- Maintenance and Repair – Equipment Handling: Used in maintenance facilities for lifting and moving heavy machinery parts, facilitating repairs and maintenance tasks.

- Warehouse Management – Inventory Handling: In large storage facilities, Double Girder Overhead Cranes manage heavy inventory efficiently, ensuring organized stacking and retrieval of items.

ISO 9001: 2015, ISO 14001: 2015, ISO 45001:2018 Certified

ISO 9001: 2015, ISO 14001: 2015, ISO 45001:2018 Certified